Subaru Legacy BN/BS (2015-2019) Service Manual: Dtc p0606 control module processor

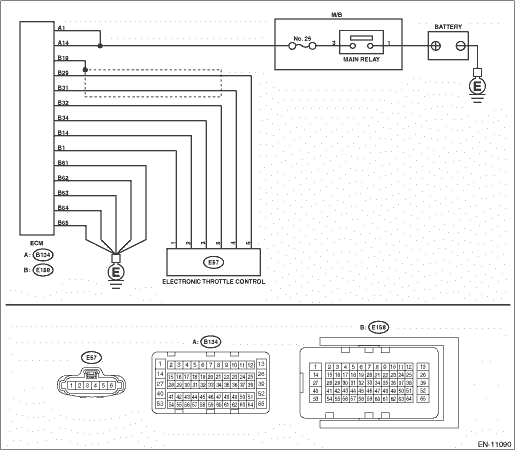

DTC DETECTING CONDITION: Immediately at fault recognition TROUBLE SYMPTOM: • Improper idling • Poor driving performance CAUTION: After servicing or replacing faulty parts, perform Clear Memory Mode Clear Memory Mode > OPERATION, and Inspection Mode Inspection Mode > PROCEDURE. WIRING DIAGRAM: • Engine Electrical System ENGINE TYPE FB (WITHOUT PUSH BUTTON START) Engine Electrical System > WIRING DIAGRAM • Engine Electrical System ENGINE TYPE FB (WITH PUSH BUTTON START) Engine Electrical System > WIRING DIAGRAM

1. OUTLINE OF DIAGNOSIS Judge as NG when the CPU operation is abnormal. (1) Instruction check (2) Software flow check (3) Software monitor check (4) If the output IC operation is abnormal (5) CAN register check 2. COMPONENT DESCRIPTION

3. EXECUTION CONDITION

4. GENERAL DRIVING CYCLE Always perform the diagnosis continuously. 5. DIAGNOSTIC METHOD Judge as NG when the following conditions are established.

Time Needed for Diagnosis: (1) — 1:2 time(s) (1) — 2:512 ms (2): 504 ms (3): 48 ms (4): 2500 ms (5): Less than 1 second Malfunction Indicator Light Illumination: Illuminates as soon as a malfunction occurs. |

Dtc p060a internal control module monitoring processor performance

Dtc p060a internal control module monitoring processor performance

NOTE:For the diagnostic procedure, refer to DTC P0606. Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0606 CONTROL MODULE PROCESSOR1. OUTLINE OF DIAGNOSISJudge as NG when the monitori ...

Dtc p0605 internal control module read only memory (rom) error

Dtc p0605 internal control module read only memory (rom) error

NOTE:For the diagnostic procedure, refer to DTC P0606. Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0606 CONTROL MODULE PROCESSOR1. OUTLINE OF DIAGNOSISJudge as NG when SUM value of ...

Other materials:

Inspection

1. Measure the resistance between connector terminals.Preparation tool:Circuit testerTerminal No.Inspection conditionsStandard1 — 2Switch OFF1 M- or moreSwitch ONLess than 1 -2 — 3Switch doorLess than 1 -2. Replace the light assembly - luggage room if the inspection result is not within the stan ...